We ensure safe, affordable, and superior hydrogen production at any location with a new generation of robust, efficient, and reliable water electrolyzers.

We ensure safe, affordable, and superior hydrogen production at any location with a new generation of robust, efficient, and reliable water electrolyzers.

Exion Hydrogen’s water electrolyzers benefit industrial gas suppliers and industrial end users in the following application domains:

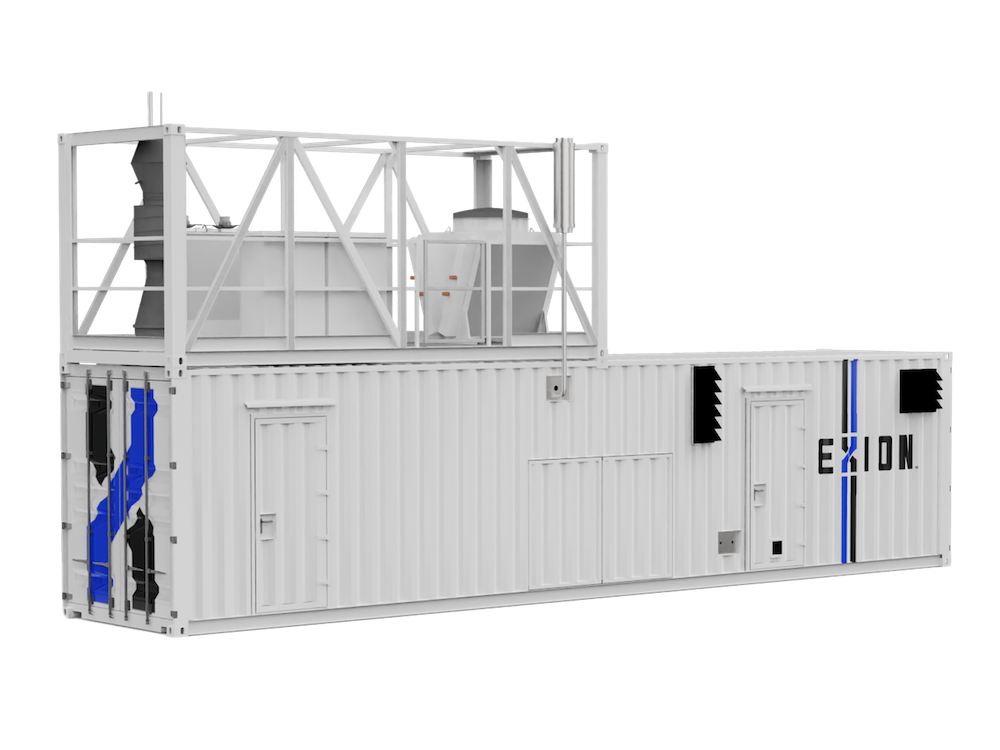

Hover over the parts of our unit to discover more

The Exion Hydrogen team consists of industry experts with decades of experience in the electrolyzer business. Based on our combined expertise and advanced research, our scientists and engineers have developed a more efficient and robust water electrolyzer for affordable on-site hydrogen production. The unit has been designed for optimal durability and safety.

We have decades of experience in the hydrogen industry. As a result, we know what works and what must be improved to further enhance the robustness, efficiency, and life span of water electrolyzers for industrial hydrogen production.

Exion Hydrogen uses only the best materials (full nickel cell stacks, extra catalyst coatings…) to secure the robustness and efficiency of our electrolyzers. Our well-qualified team in our facility in Poland is geared to build, deliver and service to the highest standards.

We enable affordable hydrogen production for industrial gas suppliers and end users of industrial, energy and mobility applications. Our systems can be easily transported, they require little maintenance, and they can be controlled remotely.

Exion Hydrogen Polskie

Elektrolizery Sp.z o.o.

Ku Ujściu 19,

80-701 Gdańsk,

Poland

NIP : 5213744833

KRS : 0000632391

Phone: +48 58 888 27 50

E-mail: info@exionhydrogen.com

Phone: +32 14 919 919

E-mail: info@exionhydrogen.com

© Exion | Cookie policy | Disclaimer | Privacy statement | Webdesign Lincelot

✔️ Machine Directive 2006/42/EC

✔️ Low Voltage Directive 2014/35/EU3

✔️ ATEX 137 1999/92/EC4

✔️ Electromagnetic compatibility 2014/30/EU5

✔️ Pressure equipment Directive 2014/68/EU (PED)

✔️ ISO 22734-1: 2008 Hydrogen generators using water electrolysis process -Part 1: Industrial and commercial applications

✔️ IEC 60204-1:2005 Safety of machinery –electrical equipment of machines –part 1 general requirements

✔️ IEC 61439-1:2011 Low voltage switchgear and control gear assemblies –part 1: general rules

✔️ IEC 61439-2:2011 Low voltage switchgear and control gear assemblies –part 2: power switch gear and control gear assemblies

✔️ IEC 60634-5-52:2009 Selection and erection of electrical equipment –wiring systems

✔️ IEC 61000-6-2:2005 EMC Part 6.2 generic standards –immunity for industrial environments

✔️ IEC 61000-6-4:2006 EMC part 6.4 generic standards -emission standard for industrial environments

✔️ EN 50160: 2019 Voltage characteristics of electricity supplied by public electricity networks

✔️ ISO 12944-5:2018 Paints and varnishes. Corrosion protection of steel structures by protective paint systems Protective paint systems

✔️ ASME Boiler and Pressure Vessel Code section VIII Div 1-ASME B31.3 Process piping-Standard for maintenance ails & escape roads